Exploring the Craftsmanship of Watch Straps: A Dive into Established Manufacturing Techniques

In the world of watches, every detail counts, and one crucial element that often goes unnoticed is the watch strap. The manufacturing techniques employed to create these essential accessories play a significant role in the overall quality and durability of the strap. In this blog post, we will delve into some established manufacturing techniques, shedding light on the intricate craftsmanship involved in creating watch straps.

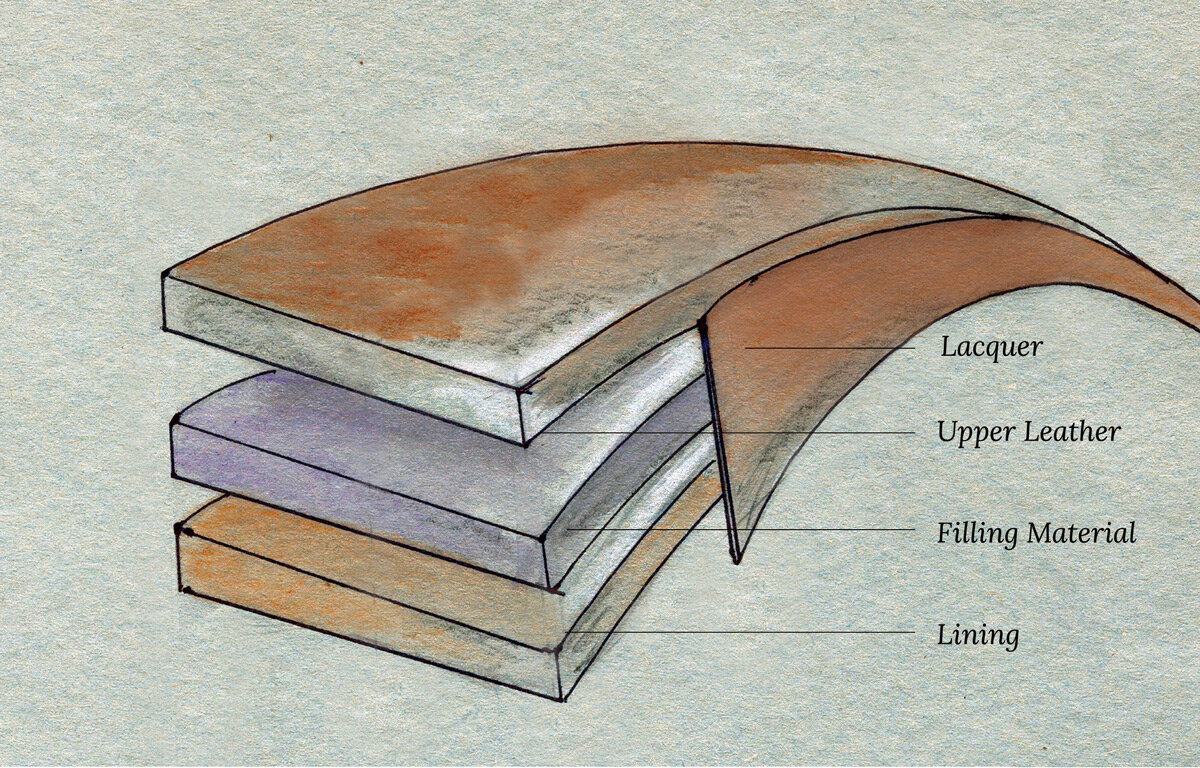

Full Remborde: Unveiling Elegance and Durability

The Full Remborde manufacturing technique stands out for its meticulous craftsmanship. In this method, the upper leather is skillfully turned around the breathable inner material, glued, and finally molded. The result is a strap that boasts stability, softness, and exceptional durability. This technique showcases the dedication of artisans in creating a high-quality and long-lasting watch accessory.

Semi Remborde: Where Gluing Meets Decoration

The Semi Remborde technique presents a unique blend of functionality and aesthetics. Here, the upper leather is pulled to the bottom line of the lining leather and sealed. While gluing is the primary binding agent, the seam serves as a decorative element, adding a touch of style to the strap. VBL uses water based glue which is sustainable and eco-friendly. This method highlights the balance between practicality and visual appeal.

Cut Edge: Precision in Every Cut

In the Cut Edge manufacturing technique, leather is precisely punched or cut into the shape of the strap before being glued. The final touch involves coloring the side edges, creating a polished and refined appearance. This method emphasizes precision in design, showcasing the artistry involved in creating a flawless watch strap.

Pilot Strap: Versatility and Durability in One

Also known as NATO Straps, Pilot Straps are celebrated for their sturdiness, sporty look, and outdoor functionality. What sets them apart is the ease with which they can be switched to complement any outfit or mood. With a single length of strap material turned and stitched to hold loops and buckle, the Pilot Strap is a testament to versatility and practicality.

Integrated: Fusion of Form and Function

In the Integrated manufacturing method, the strap becomes an integral part of the watch case. Crafted to exact dimensions, the strap is fused seamlessly with the case, offering a harmonious and cohesive design. This technique can be incorporated into Full Remborde, Semi Remborde, and Cut Edge Straps, enhancing the overall aesthetic appeal of the timepiece.

Hybrid Strap: The Best of Both Worlds

For those who desire a fusion of luxury and performance, Hybrid Straps are the epitome of sophistication. Crafted from top-quality materials, these straps combine graded performance rubber and PU materials to offer a blend of classic style and functionality. The Hybrid Strap is a symbol of innovation in watch strap manufacturing, catering to individuals who appreciate both luxury and performance.

The world of watch straps is a fascinating realm where craftsmanship and innovation converge. Whether it's the meticulous Full Remborde technique, the decorative Semi Remborde, the precise Cut Edge method, the versatile Pilot Strap, the seamlessly Integrated approach, or the sophisticated Hybrid Strap, each manufacturing technique tells a unique story of dedication and artistry. As you explore the world of watches, take a moment to appreciate the craftsmanship behind the straps that adorn these timepieces, turning them into timeless pieces of art.